Grande Prairie Pulp Mill celebrates 50-year anniversary

The Grande Prairie Pulp Mill is celebrating 50 years of operations on Monday, July 17, and has released the following statement regarding this accomplishment.

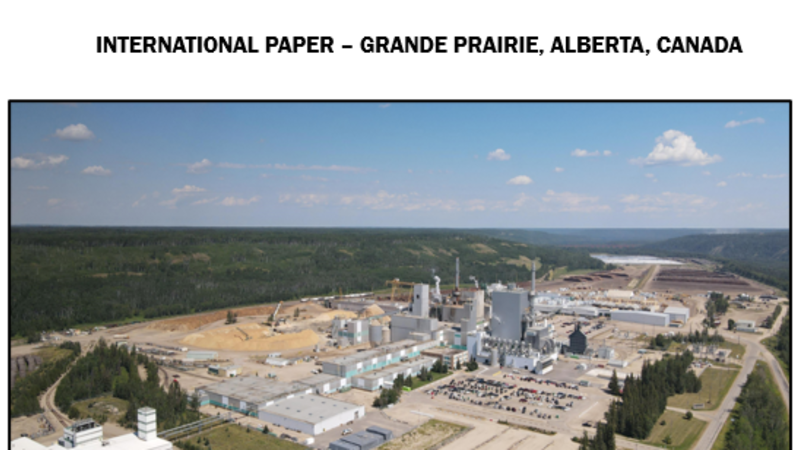

” The Grande Prairie Pulp Mill started their operation for the first time, on July 17, 1973, when their first bale of pulp was produced. The International Paper (NYSE: IP) Grande Prairie Mill has been the backbone of our community for years, providing careers for many Albertans and product for customers all over the world.

Every day the world moves forward with new ideas, new technologies and new priorities. And, everyday International Paper works to make the world better, safer and more sustainable so their customers, employees, shareholders and communities can thrive.

An Overview of the Mill